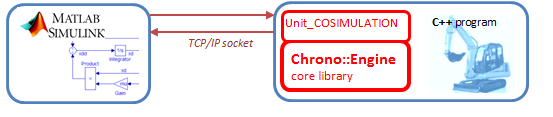

This tutorial explains how to use co-simulation to simulate a hydraulic system that moves a simple mechanism. The hydraulic system is managed by Simulink, while the mechanism with moving parts and joints is simulated by Chrono. This is enabled by the COSIMULATION module.

The approach described can serve as a template for complex scenarios in which mechanisms with multiple hydraulic cylinders actuate moving parts. In general, Simulink features are used for hydraulic subsystem simulation and controls, whereas Chrono can be used for the remaining components of the mechanical system:

Prerequisites

The prerequisites for this tutorial are:

- The Chrono COSIMULATION module should be properly installed/working.

- Simulink must be installed.

- The Matlab Instrument Control Toolbox should be installed.

- The Matlab SimHydraulics Toolbox should be installed.

Background

Two way co-simulation draws on two simulation tools which simultaneously simulate (advance in time)

the two subsystems in which the original system is partitioned. Once in a while the two solvers (simulation tools) synchronize to exchange data after which they proceed independently until the next synchronization time. This periodic data synchronization is necessary because the subsystems are coupled. For tightly coupled subsystems the synchronization happens very often.

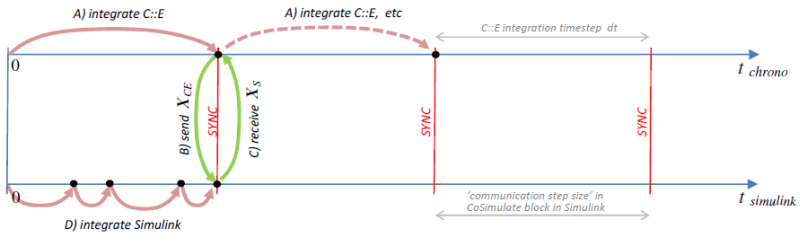

There are many approaches to co-simulation. The method described in this tutorial is quite simple - it is based on the following pattern of interaction between Chrono and Simulink:

In the schematic above, suppose that the system is defined by variables \( \mathbf{X} = \{ \mathbf{X}_{CE}, \mathbf{X}_{S}\} \), which are splitted so that Chrono deals with \( \mathbf{X}_{CE} \) while Simulink deals with \( \mathbf{X}_{S} \).

The sequence of operations is:

- A) the Chrono simulator advances by a time step \( dt \), up to the synchronization point;

- B) the \( \mathbf{X}_{CE} \) variables are sent from Chrono to Simulink using a TCP/IP socket;

- C) the \( \mathbf{X}_{S} \) variables are sent from Simulink to Chrono using a TCP/IP socket;

- D) the Simulink simulation advances up to the synchronization point. Note that Simulink could use variable-step integration, hence it could take more than one step to reach the synchronization point, see figure.

This pattern is repeated through to the end of the simulation.

In this implementation, the value of \( \mathbf{X}_{CE} \) that is received by Simulink is interpolated linearly during the timestep(s) advancement that reaches the sync time; on the other hand, the \( \mathbf{X}_{S} \) values received by Chrono are kept constant as in a Zero Order Hold (ZOH).

In this type of cosimulation the 'slow' integrator, that is Chrono, precedes the high-frequency integrator, that is Simulink. However, the opposite could be done as well. Other more sophisticated interpolation-extrapolation concepts could be devised - for example using extrapolation instead of ZOH or using higher-order interpolation for \( \mathbf{X}_{CE} \) received in Simulink.

When Chrono precedes Simulink and using extrapolated \( \mathbf{X}_{S} \) values is like having a latency of \( dt \) in the cause-effect relationship between Chrono and Simulink. When the coupling between the two subsystems is tight, too large a \( dt \) can cause numerical instability problems. Unfortunately, keeping \( dt \) very small to address stability issues will likely impact negatively the simulation times.

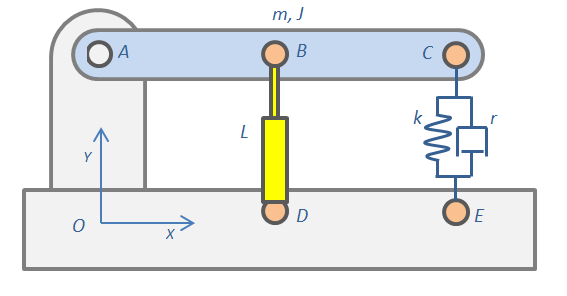

The system

The following mechanism is considered in this tutorial: a lever with a revolute joint in A and a linear actuator L between points B and D:

Although Chrono already has methods to define linear actuators, Simulink and its SimHydraulics toolbox are used to produce an advanced model of a hydraulic actuator with valves, piping, pumps, feedback control, etc. The yellow actuator will be simulated in Simulink, the rest in Chrono.

The Simulink model

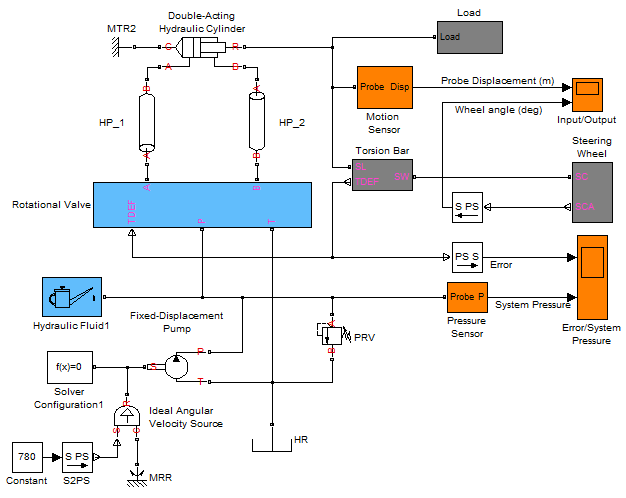

First, open Simulink and create a model of a hydraulic actuator with a pump and a valve. To keep it simple, just load the Power assisted steering mechanism demo of SimHydraulics (sh_hydraulic_power_assisted_steering.mdl). It includes a ready-to use system where a piston is moved back and forth depending on the feedback control of the rotation of a steering wheel:

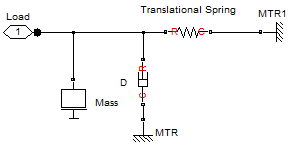

Note that the original example used a mass-spring-damper system modeled with SimScape Simulink blocks; this can be seen by double clicking on the Load block to expand it:

Replacing the Load block with a Chrono mechanical load calls for the following steps:

- Delete the Load block.

- Open data/cosimulation/CEcosimulation.mdl, copy the CoSimulate block and paste it into the model, near the piston.

- Select CoSimulate and use menu Edit/Link Options../Break link so that you can modify it

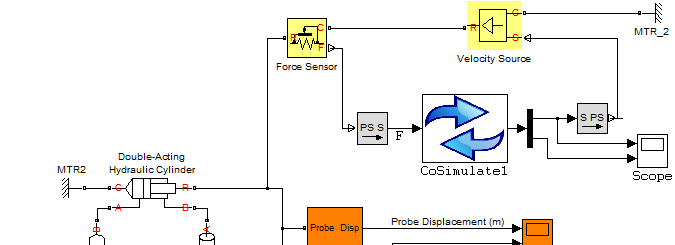

- Create the following connections between the piston and the CoSimulate block:

The CoSimulate block is an interface that sends its input vector of variables to Chrono and gets back an output vector at fixed time intervals. Specifically,

- Simulink sends the force of the piston to Chrono. Chrono will apply that force to the mechanical system between the 'B' and 'D' hinges, so it will compute speed and displacement.

- Vice-versa: Chrono sends speed & displacement of the piston to Simulink. Simulink will enforce that speed and displacement to the piston so that it will compute the force.

This explains the need for those two yellow blocks: one is the SimScape Simulink block used to get a reaction force (in this example in the rod of the piston) while the other is used to impose a motion (in this example to the rod of the piston). The PS S and S PS grey blocks are used to convert SimScape and SimHydraulics signals from/to Simulink signals.

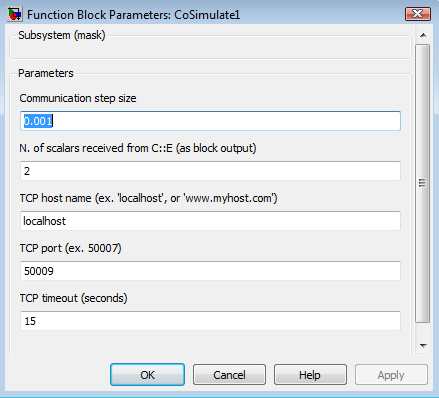

Double click on the CoSimulate block and set its parameters:

Semantics:

- Communication step size: controls how frequently Chrono and Simulink exchange information. This example needs a very small step size because this is a stiff problem (as is often the case with hydraulic problems) so larger steps would cause numerical stability issues.

- N. of scalars received from Chrono must match the number of variables sent from the Chrono-side using C++. In this example what gets sent is 1) velocity and 2) displacement of the rod.

- TCP host name: leave 'localhost' if you run both simulators on the same computer, otherwise if you have Chrono on a different machine, you provide the IP address here.

- TCP port: any non-firewalled, non-used port can work here. For instance, use 50009.

- TCP timeout: if Chrono does not respond within this period, the simulation is stopped.

Next, save the entire model with a proper name. This example already provides a ready-to-use model: data/cosimulation/test_cosim_hydraulics.mdl

The Chrono model

You can find a ready-to-use example in src/demos/cosimulation/demo_COSIM_hydraulics.cpp. The steps implemented in this program are as follows:

- Use the 'try...catch' statements around socket communication operations because errors in sockets might throw exceptions.

- Create a Chsystem and populate it with a truss, a moving body, and a revolute joint.

- Now create create a 'dead' linear actuator between two points using a ChLinkTSDA with zero stiffness and damping. This will be used to apply the force between the two bodies as a cylinder with spherical ball ends.

- Create a spring-damper to have some load when moving, and configure the system's solver precision.

- Add a socket framework object (a unique copy to be used through all the program) and a cosimulation interface.

- Prepare the two column vectors of data that will be swapped back and forth between Chrono and Simulink:

- receive one variable from Simulink (the hydraulic cylinder force);

- send two variables to Simulink (the hydraulic cylinder velocity and displacement).

- Wait for client (Simulink) to connect. Note that in this implementation Chrono is the server and Simulink the client.

- Upon establishing a connection, the simulation is ready to begin. Note that 'dt' must be the same with the value entered in the CEcosimulation block.

- Finally, provision for exception catching in running into any trouble with the socket connection.

Run the cosimulation

All the tools are ready for the cosimulation at this point. The next steps:

- Compile the Chrono program;

- Run the Chrono program; it will enter a wait state because it is waiting Simulink to connect;

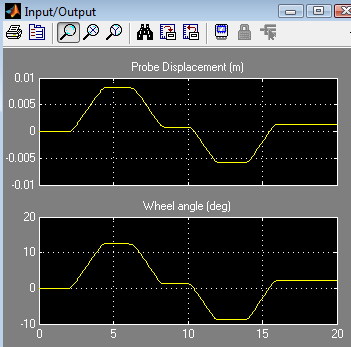

- Open the ''Input/Output'' orange scope block in Simulink, simply to plot some results.

- Run the Simulink model by pressing the '>' button in the Simulink interface;

The two codes will run in parallel and will exchange data periodically up to the end of the simulation or up to when one presses 'stop' or aborts the Chrono program.